What Are You Looking For?

What Are You Looking For?

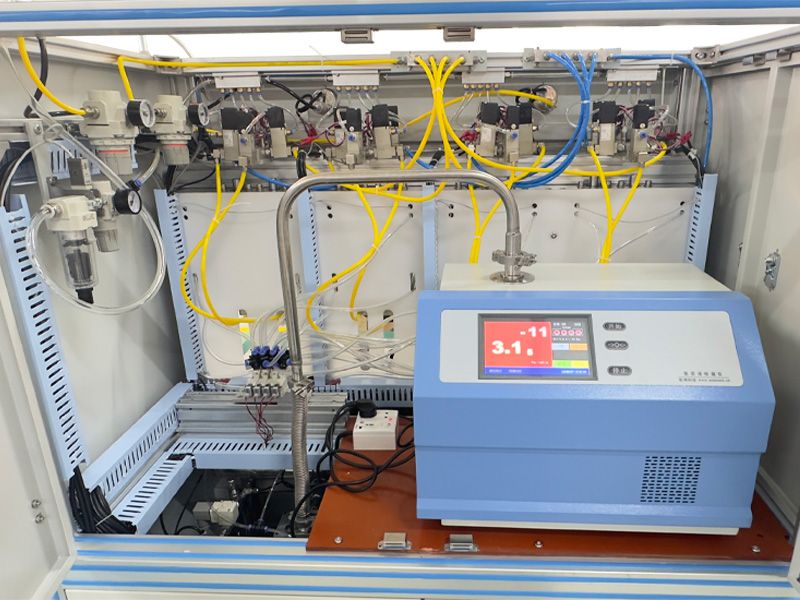

The Relay Helium Mass Spectrometry Leak Detector is a high-precision testing device designed specifically for the electric vehicle industry. It uses the world's leading helium mass spectrometry leak detection system to ensure the absolute reliability of automotive relays and electronic components in harsh environments.

Item No. :

HJ146Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

Türkiye,ChinaSupply Ability :

1 sets per 90 daysLead Time :

90 Working DaysConventional packaging :

PlywoodRelay Helium Mass Spectrometer Leak Detector

Product Introduction:

In our work with electric vehicle manufacturers and electronic component suppliers, we deeply understand the importance of "seal reliability" to product quality. This is more than just a machine; it's a guardian of your product's safety.

This helium mass spectrometer leak detector features a user-friendly design. We've optimized the testing process specifically for the production pace of the electric vehicle industry, significantly improving testing efficiency. Even on high-speed production lines, we ensure that every component's seal meets automotive-grade standards. We believe that excellent testing equipment should be a booster of production efficiency, not a bottleneck.

The HJ146 inherits HJ Test System's 20 years of experience in leak detection technology. Every design detail reflects our understanding of the unique needs of the electric vehicle industry. We understand that every component you produce is a vital component for the reliable operation of electric vehicles.

Product Features:

Automotive-grade sensitivity testing: Meets the most stringent automotive electronics reliability standards

High-speed automated operation: Designed specifically for the mass production needs of the electric vehicle industry, enabling rapid testing and data analysis

Fast startup and response: Device startup time is under 2 minutes, and response time is less than 0.5 seconds, adapting to production line rhythms

Multiple leak detection modes: Supports vacuum, sniffing, and positive pressure leak detection modes to meet the testing needs of various electronic components.

International Reference Standards:

IEC 60068-2-17: International Electrotechnical Commission Standard "Environmental Testing Part 2-17: Sealing Tests"

ISO 16750-3: Road Vehicles — Environmental Conditions and Testing for Electrical and Electronic Equipment — Part 3: Mechanical Loading

ISO 9001:2015: Quality Management System Standard, ensuring consistent quality throughout the entire product process

Technical Parameters:

| Project | Parameters |

| Number of Workstations | 8 |

| Dimensions | 2000mm*2500mm*2000mm |

| Production Rate | 500 pieces/hour |

| Ambient Temperature | 0-40°C |

| Power Supply | 380V, 3-phase, 5-wire, 50Hz |

| Power Consumption | 5kW |

Product Applications:

Electric Vehicle Industry: Testing battery management system relays, charging system relays, and drive system control relays

Automotive Electronics: Ensuring the sealing performance of electronic control units (ECUs), sensors, and connectors

Electronic Component Manufacturing: Testing the leakage rate of components such as miniature sealed relays, transformers, and inductors

Detail pictures:

Hot Tags :